Helping Our Clients Achieve “Net Zero by 2050” by Thinking Ahead in Our Life Cycle Assessments

Incorporating future scenarios into LCAs can help climate-related innovators evaluate impacts and opportunities, and use R&D resources efficiently

“Net Zero by 2050” is getting worldwide traction as a goal for governments, companies, investment firms, and other organizations. Reducing CO2 emissions to net zero levels by mid-century would help in the effort to limit the long-term increase in average global temperatures to 1.5 degrees C, and thus help minimize the myriad societal disruptions of climate change.

While this is a welcome development, our broad dependence on fossil fuels makes it a very ambitious goal. A sense of the task’s magnitude is provided by the International Energy Agency (IEA) in its report, “Net Zero by 2050: A Roadmap for the Global Energy Sector”. It states (emphasis added):

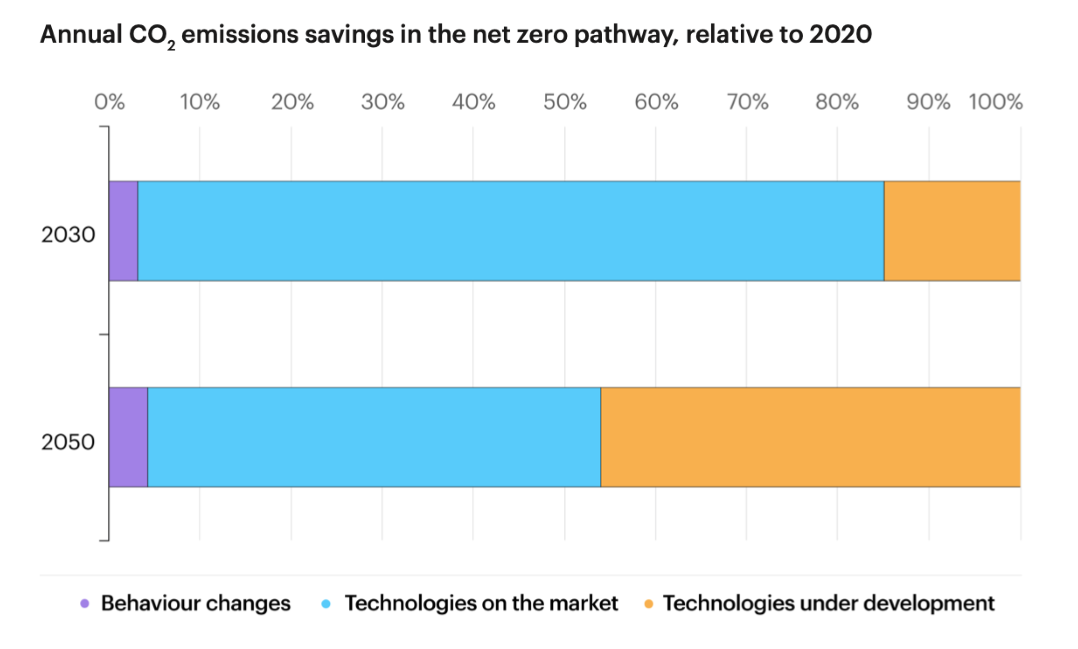

Most of the global reductions in CO2 emissions through 2030 in our pathway come from technologies readily available today. But in 2050, almost half the reductions come from technologies that are currently at the demonstration or prototype phase. In heavy industry and long-distance transport, the share of emissions reductions from technologies that are still under development today is even higher.

Source: IEA.org

This highlights the imperative need for successful climate-related innovation. And a key ingredient in that innovation process will be the insights derived from robust, comprehensive life cycle assessments (LCAs). They’re an essential tool for technology developers who are evaluating impacts and opportunities and seeking to utilize their R&D resources in the most efficient and timely way. We see this in our work with many clients who are currently at that demonstration/prototype phase of development.

LCA is complex enough for products reaching market now. In the case of forward-looking advancements with long gestation times, there’s the added wrinkle of having to anticipate how much positive impact a technology will have in a future scenario when (presumably) the grid is cleaner and newer, less-impactful technologies have replaced some of our current points of comparison. System-level thinking is always essential for LCA practitioners, and particularly so in these longer-term analyses.

A good example is our work on behalf of Biofine Developments Northeast, which is developing a process to produce ethyl levulinate (EL) biofuel from waste biomass residues (wood chips, sawmill waste, wastepaper, etc.) and plant residue. Our first collaboration was a 2009 LCA study of production and use of the EL fuel for transportation purposes; we later conducted two life cycle assessment (LCA) projects that helped Biofine win support from the home heating oil industry.

More recently, we’ve extended that work to look at greenhouse gas emissions associated with broad use of EL as a heating fuel, including production at pilot and commercial scale using two alternative feed sources (forest residues and post-consumer wastepaper). Anticipation of future scenarios comes into play because the EL production process generates co-products including surplus electricity, formic acid, and (with wastepaper feedstock) furfural, all of which avoid impacts elsewhere. But in an era when the grid is cleaner and EL production has displaced other methods of making formic acid and furfural, the credits for avoided impacts go down.

Heating with EL would still have very low impact, but the situation illustrates how we have to adapt our thinking for long-term development projects. Today we’re largely comparing new ideas against impact-intensive legacy processes; our hoped-for ongoing success in broadly reducing carbon emissions will mean ever-tighter standards for impact reduction. From a high-level perspective that’s a good thing, but it’s one more challenge for technology development organizations.

Consider another client of ours, which is working on a way of producing an important industrial commodity from scrap material in a process that’s much less energy- and chemical-intensive than traditional methods. Promisingly, the alternative process that’s been proven at the demonstration stage gets even more efficient as it scales up, with impacts going down an additional 33 to 75 percent — and a cleaner electricity grid would make things even more favorable.

We’re very excited about the prospects for this technology, but again, the points of comparison will not remain static. Companies using the traditional production process will also benefit from a cleaner grid; in addition, spurred by the Net Zero imperative, they could find impact-reducing modifications that have thus far eluded them. So, our analysis included comparisons for several future scenarios to ensure that our client had full visibility.

Achieving Net Zero by 2050 won’t be simple. While we can hope for transformative breakthroughs, like fusion energy production or a clever new method of removing carbon from the atmosphere, it’s most likely that the task will have to be accomplished via hundreds or thousands of smaller advancements. The innovators pursuing them are among today’s technological heroes and supporting them with insightful LCA results is central to EarthShift Global’s mission.

Is your organization developing a new technology with impact reduction potential? We can help you stay on track towards your goals — contact us at (207) 608-6228, or [email protected].